Last week, our colleagues Feline and Yvette ventured to Kenya for an exciting training session: Product Quality classification along the beans value chain! A total of 27 individuals participated in this training, which focused on beans, marking the inaugural run of this new Q-Point training! The training was part of project: Market driven training programs for the horticultural sector in Kenya (TMT+23-00034) – Q-Point (q-point-bv.nl)

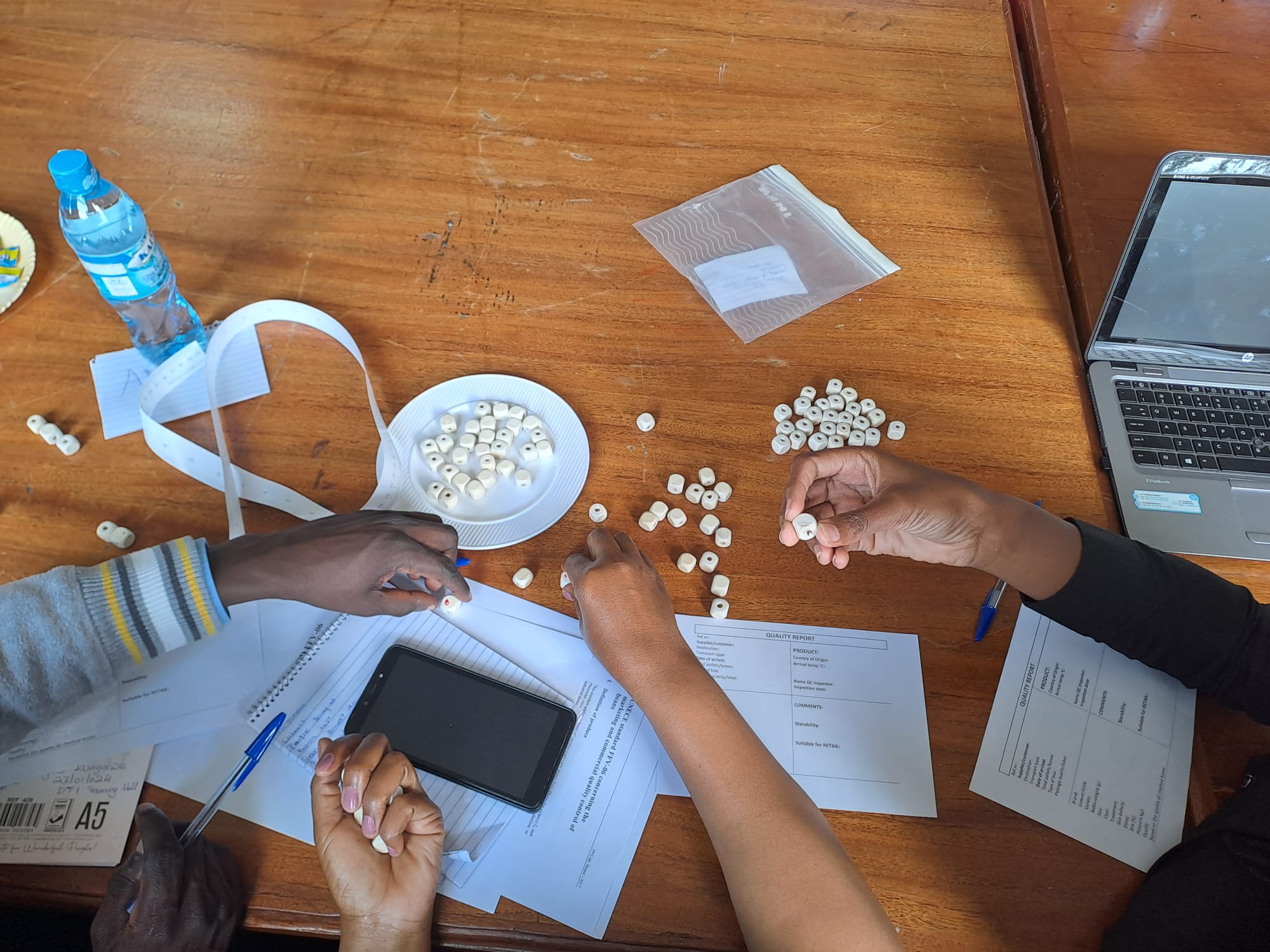

During the training, special emphasis was placed on French beans, Snow Peas, and Sugar Snaps. The group familiarized themselves with the various standards for beans and how to interpret them. Using the UNECE standard as a foundation, participants practiced with sample beads marked with defects across different classifications. The findings needed to be documented objectively rather than subjectively in an inspection report. The groups engaged in spirited discussions and problem-solving, leading to some amusing discoveries.

Group work – beans assessment

Group assignment

During the training

Following the training sessions, we embarked on a field trip by bus to explore the world of beans! The fundamental knowledge about beans proved invaluable during our visit to Gorg Farm. The warm explanations we received about runner beans, salad unions, baby corn, and the operations at the Gorg Farm packhouse, coupled with the participants’ inquiries, provided deeper insights into quality standards. In summary, it was an engaging and practical day where theory met practice.

Field visit Gorg Farm

Field visit Gorg Farm (2)

After deepening our understanding of bean products, utilizing our senses, and inspecting beans to write Quality Control (QC) reports, many quality-related topics intertwined. It was gratifying to see participants recognize aspects of product knowledge through their visit to Gorg Farm. Following a theoretical segment, we transitioned to the interactive aspect of utilizing the 5 senses. A minor logistical mishap with the preparation of tasting cups was serendipitously resolved through an improvisation—a fortunate accident! The beans we had brought along had accidentally ended up in the freezer, which they didn’t quite appreciate upon thawing out. It provided a seamless segue to applying the 5 senses to these rejected beans! 😉

Visit Gorg Farm Packhouse

After lunch, it was time to apply all the acquired knowledge to evaluate Class I beans purchased from the supermarket and document our findings in written QC reports accompanied by photos. It was encouraging to witness participants engaging in discussions about their observations and consulting the UNECE bean standard.

The final day of the training primarily focused on communication. It was heartening to witness groups actively engaging in practical assignments. The task of brainstorming solutions for rejected products yielded fascinating insights into the issue of food wastage. After addressing any remaining questions and completing evaluations, the training concluded with this group.

It was a successful training week, and we’ve already heard from participants that they have plenty of material to implement within their organizations, with some even beginning during the training itself! We eagerly anticipate the continuation of the project and forthcoming training sessions. Thanks to all for your dedication—FPEAK, Kenya School of Agriculture, and every training participant alike.

All training participants